PRODUCTION CAPABILITIES

LongHui Packaging, which is our main factory, was established in 2014 and is headquartered in Jiangyin City, Jiangsu Province, China. With ongoing investments and a total construction area exceeding 40,000 square meters, LongHui Packaging operates some of the most advanced flexible packaging production facilities in the industry.

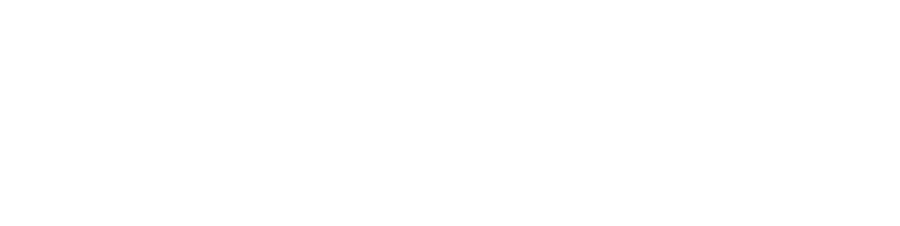

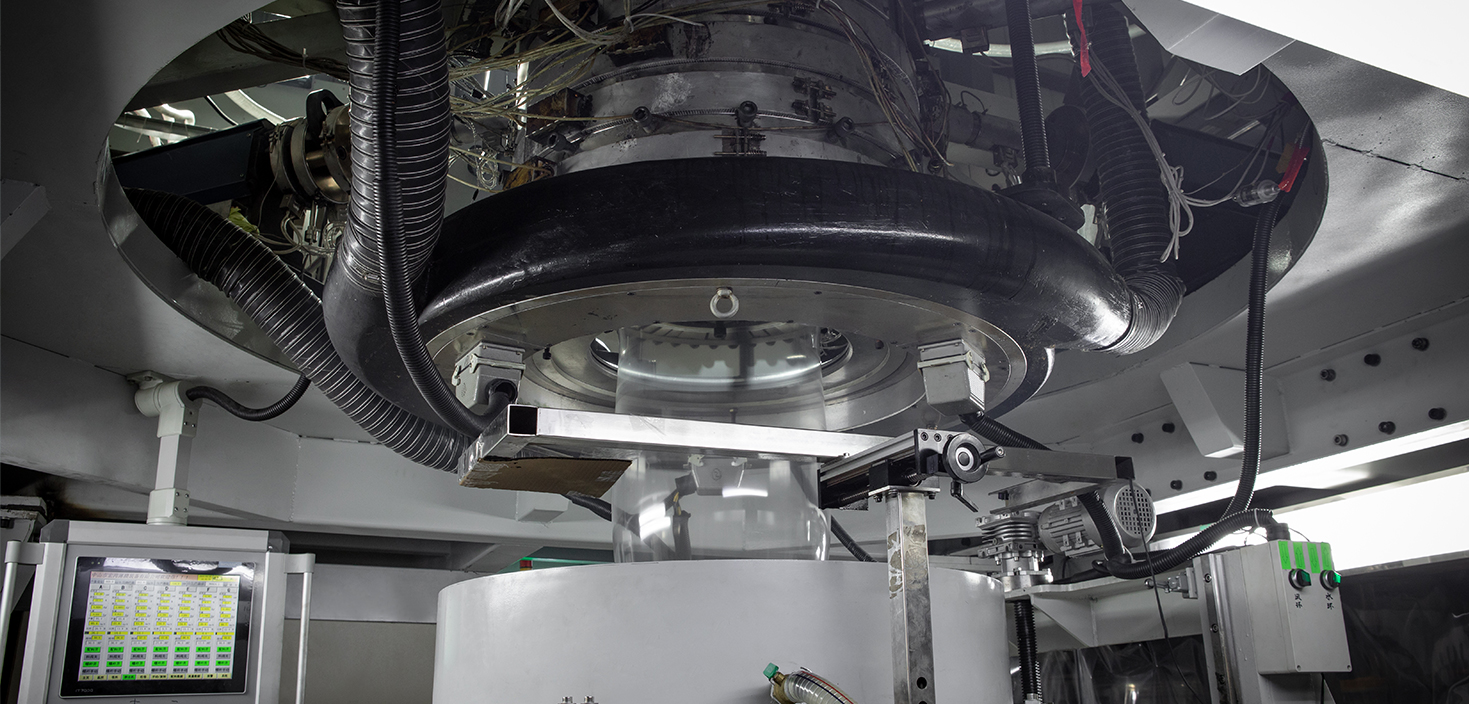

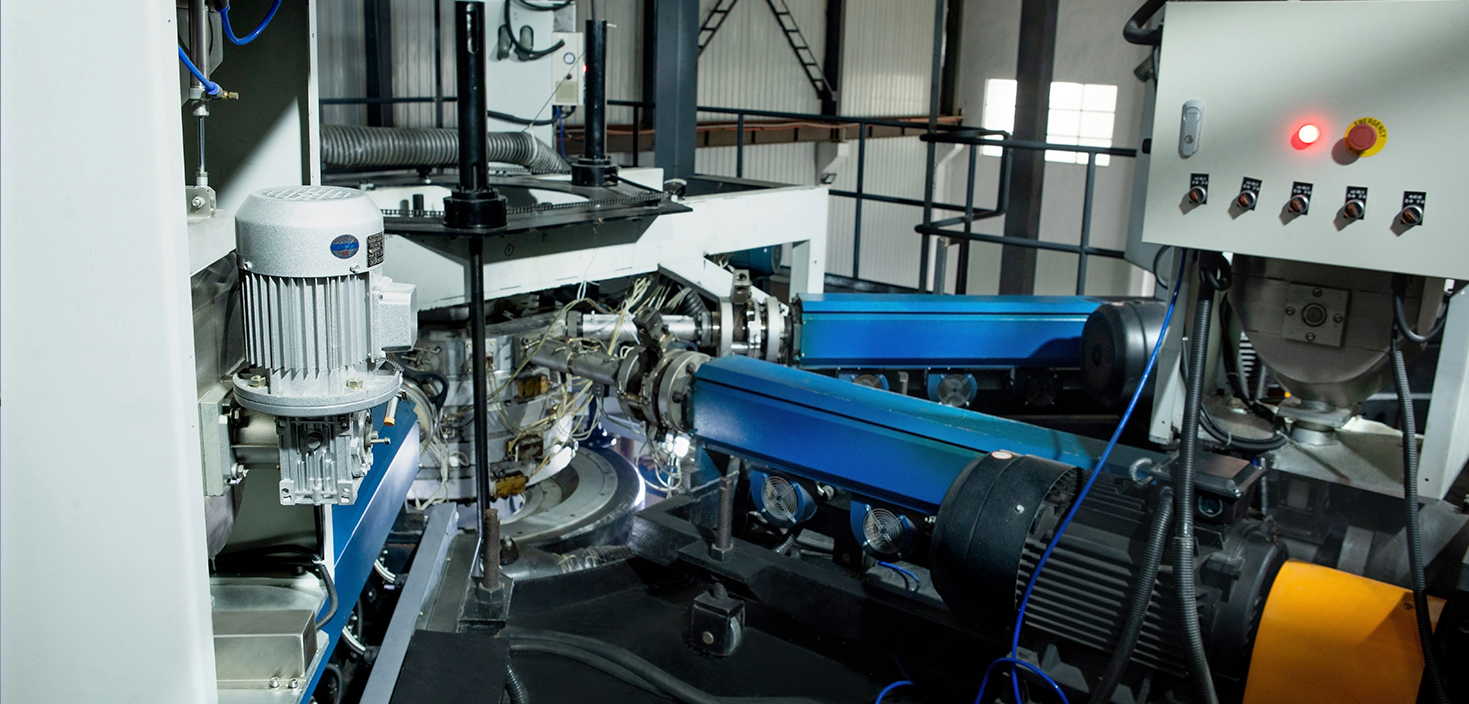

Our primary production equipment, sourced from renowned global and domestic manufacturers,includes multiple high-speed printing lines, high-speed lamination lines, blown film lines (including two advanced coextruded film lines), high-speed slitting lines, and multiple bag-making machines. We specialize in producing flexible packaging for the food and beverage,daily chemical, agrochemical, industrial product, and healthcare industries. Our capabilities include manufacturing composite films and bags made from plastic, coated plastic,aluminum-coated materials, and aluminum foils.

Our facility is equipped with comprehensive testing devices such as oxygen/moisture permeability testers, gas chromatographs, tensile testers, coefficient of friction testers, heat sealers, and more.

LongHui Packaging has passed the QS on-site audit and obtained QS certification. We have also been awarded ISO 9000 certification. Over the years, LongHui has successfully completed on-site audits by many renowned domestic and international companies, including Sanxing Corporation (Japan), Want Want Group, Liby Group, Yili Group, Mengniu Group, Nestlé, and more, paving the way for successful cooperation.

In addition to LongHui, we have several affiliated factories that enhance our production capacity and flexibility. These close partnerships ensure that we can reliably deliver both quality and quantity to meet our clients' needs.

We are committed to putting customers first and providing superior packaging solutions.

Manufacturing Capability

Specialty

We are committed to providing customers with the highest quality products and services. We have established a professional experimental center equipped with comprehensive inspection and testing equipment, including oxygen and moisture permeability meters, gas chromatographs, tension meters, friction coefficient meters,heat sealing meters, haze meters, microscopes, and more. This equipment allows us to effectively control physical and chemical indicators throughout the entire process, from raw material to finished product and delivery. Additionally, we have introduced fully automatic solvent filling equipment to ensure consistent and stable quality for each order.

- Online Inspection

- Double-side Registration

- Locate Coating

- Anti-counterfeiting(barcode/2D Code)